SASSO MAKES IT EASY

TO GET YOUR SHINE ON

In the 1970s, Sasso revolutionized stone fabrication by inventing the vertical edge polisher, transforming how the industry approached countertop finishing. Today, our RDM Compact brings that innovation to any shop as an affordable, high-production solution. Process flat edges at three feet per minute on any material with a machine engineered for ease of use and simple maintenance. The RDM delivers professional results without complexity.

Our FLAT production series represents the evolution of straight-edge perfection. These high production machines excel at high-volume flat polishing with precision micro bevels, combining speed with consistency to maximize throughput.

Sasso's profiling line machines specialize in complex radius profiles including full and demi bullnose, bevels, and crescents. The Bull 126 features a 6+2 bevel configuration for specialized applications, while our flagship Revolution machine combines 6 toroidal spindles, 2 bevel heads, and 5 flat polishers for the most demanding production needs.

RDM FLAT POLISHER

OPTIONAL TALL FEED SUPPORT

Every component has been refined through decades of real-world fabrication. Motors mounted where water can't reach them. Spindles accessible

SIMPLE AND FAST

AUTOMATED FLAT POLISHER

The RDM is 50 years of innovation in one elegantly simple machine

Every component has been refined through decades of real-world fabrication. Motors mounted where water can't reach them. Spindles accessible from the front. A CNC-machined mounting plate that makes setup straightforward.

Six polishing heads and two micro-bevel spindles process flat edges at three feet per minute on any material—granite, quartz, or marble. Consistent, professional results without maintenance headaches.

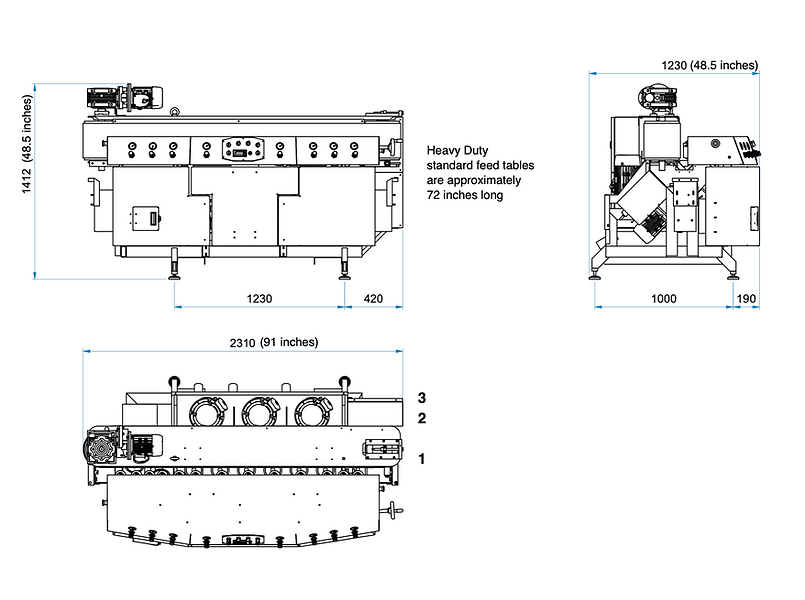

The RDM Compact fits modest shop spaces at 91" x 48", yet delivers industrial-grade performance. Hot-dip galvanized steel framework ensures decades of corrosion-free service. Straightforward controls mean anyone in your shop can run it.

CNC MACHINED SPINDLE PLATE

Precision-machined mounting ensures level alignment. Easy setup, maintains accuracy over years of production.

EXTERIOR MOUNTED MOTORS

Motors mounted outside the water zone. No encapsulated bearings to fail. Extended service life, reduced maintenance.

FRONT-ACCESSIBLE SPINDLES

Service all spindles from the front. Quick tooling changes keep production flowing.

HOT-DIP GALVANIZED STEEL FRAME

Corrosion-resistant framework built to last decades. Paint chips and peels, galvanization doesn't.

6 POLISH HEADS - 2 BEVELERS

Process flat edges from rough to polish in a single pass. Dedicated bevel spindles with adjustable stops for precision finishing.

COMPACT 91" x 48" FOOTPRINT

Fits space-constrained shops. Easy to position and install. Modest footprint, full performance.

THREE FEET PER MINUTE FEED RATE

Process backsplash and countertops rapidly. Consistent speed across all materials.

SIX-FOOT HEAVY-DUTY FEED TABLES

Robust infeed and outfeed tables support long pieces safely. Optional tall support system available for oversized work.

SIMPLE MAINTENANCE DESIGN

Large access doors, common parts, no specialized tools. Designed for fabricators who service their own equipment after warranty.

THE FLAT SERIES

FLAT SERIES ARE CUSTOMIZABLE

The FLAT series scales with your production needs. Start with a 6+2 configuration (six polishing heads, two micro-bevel spindles) for efficient flat edge processing, or step up to a 10+6 powerhouse for maximum throughput. Every configuration delivers three feet per minute processing speed on granite, quartz, or marble. More spindles means higher capacity and faster feed rates.

Talk with our team to configure the right machine for your volume and budget. Need capacity for backsplash production? A 6+2 handles it. Running high-volume countertop fabrication? Scale up to 8+4 or 10+6. The modular design lets you invest in the spindles you need.

Consistent, professional results without maintenance headaches, regardless of configuration.

SASSO FLAT 8-4

PRODUCTION FLAT POLISHING

SASSO FLAT FOR SERIES PRODUCTIVITY AND PERFORMANCE

Flat edge polishing for fabricators with serious production demands.

The FLAT Series is a horizontal line machine configured at order to match your production requirements. Choose 6, 8, or 10 polishing heads based on volume. Select 2, 4, or 6 bevel heads for micro-bevels. The configuration you order is what you get, purpose-built for your shop.

Horizontal feed makes handling oversized countertops and large-format material straightforward. With 8 or 10 heads, processing speeds increase substantially over compact machines.

Hot-dip galvanized steel framework. Optional calibration spindles and multi-purpose heads available when ordered. Configure the machine that fits your production reality.

The FLAT Series: horizontal feed, custom configuration, built for high-volume flat edge work.

SCALABLE POLISHING HEAD CONFIGURATION

Choose 6, 8, or 10 polishing heads based on production volume. Configured to match your shop requirements.

CUSTOMIZABLE BEVEL HEAD OPTIONS

Configure with 2, 4, or 6 bevel heads for precision micro-bevels. Mix flat and bevel heads to match production needs.

HANDLES 2CM TO 10CM MATERIAL THICKNESS

Process standard 2cm countertops through thick 10cm material. Consistent results across all thickness ranges.

PROGRAMMABLE STOP POLISHES

Stop polishing is no problem on the Flat series. Touchscreen programming makes setup fast and repeatable.

DRIP EDGE CAPABILITY

Create drip edge profiles, a detail popular in European fabrication.

OPTIONAL RODDING SYSTEM

Cuts channels for reinforcing rods in fragile stone. Strengthens delicate materials for safe installation.

COLOR TOUCHSCREEN CONTROLS

Latest generation touch interface simplifies programming. Visual job preview and parameter adjustment.

OPTIONAL MULTI-PURPOSE SPINDLE

Expands capability beyond standard flat and bevel operations. Available when configured at order.

BULL 126 PROFLING

WHEN YOU NEED MORE PROFILES

BULL 126 PRODUCES RAPID TOROIDAL EDGES WITH EASE

The Sasso Bull 126 delivers professional edge finishing at a practical price point. This versatile machine handles full bullnose, demi-bullnose, bevels, and flat edge work with consistent quality.

Built for fabricators who need reliable performance without complexity.

The 6+2 configuration features six toroidal spindles for radius profiles plus two bevel heads. Intuitive controls and straightforward setup means you're polishing within minutes of installation.

Sasso engineering focuses on what matters: consistent results, minimal maintenance, and straightforward operation

6 TOROIDAL SPINDLES FOR RADIUS PROFILES

Full bullnose, demi-bullnose, and custom radius edges with precision and consistency.

2 BEVEL HEADS FOR CHAMFERS AND ANGLES

Versatile configuration handles flat bevels and angled edge work with ease.

HOT-DIP GALVANIZED FRAME PREVENTS CORROSION

Paint chips, peels and rusts over time. All Sasso machinery is hot galvanized to prevent rust and protect your investment.

COMPACT FOOTPRINT, MAXIMUM CAPACITY

Process large countertop pieces while taking up minimal shop space. Smart design maximizes productivity per square foot.

SIMPLE CONTROLS, IMMEDIATE PRODUCTIVITY

Intuitive interface requires minimal training. Get your team polishing professionally within minutes of setup.

ANDLES GRANITE, MARBLE, AND QUARTZ

Versatile processing across all stone types. One machine for all your edge finishing needs.

PROVEN RELIABILITY, MINIMAL MAINTENANCE

Built with quality components designed for years of daily production. Less downtime, more billable hours.

EASED MADE EASY

EASED EDGE IS NOW POSSIBLE

THE REVOLUTION CHANGED

THE GAME FOREVER

The Revolution combines flat and toroidal technology for high-speed edge production. Process eased edges with micro radius at feed rates up to 24 inches per minute. Six toroidal spindles handle bullnose and radius profiles while five flat polishing heads deliver eased edges with speed and precision.

Built for production, the Revolution features a calibration spindle, two 45-degree beveling spindles, and articulating toroidal heads on rocking arms for consistent results. Process 2cm to 6cm material with radii up to 30mm. Feed rates from 4 inches to 6 feet per minute let you optimize for quality or throughput.

Digital touchscreen controls make programming simple. Rear access speeds tool changes. Marine-grade fiberglass covers and premium components ensure the Revolution handles daily production demands. Optional automated rodding and drip edge capabilities expand what's possible.

SIX TOROIDAL SPINDLES ON ARTICULATING ARMS

Precise radius profiles including full and demi bullnose. Position one regulated for diamond tools.

FIVE MICRO-OSCILLATING FLAT POLISHING HEADS

Rapid eased edge processing with minimal aris. Feed rates of 18-24 inches per minute.

CALIBRATION SPINDLE AND BEVEL HEADS

One calibrator/rectifier spindle for dimensional accuracy. Two beveling spindles for efficient profile preparation.

DIGITAL TOUCHSCREEN FOR EASY PROGRAMMING

User-friendly interface simplifies operation. Real-time feed rate monitoring.

REAR ACCESS FOR FAST TOOL CHANGES Easy spindle access from back of machine. Interior components easily reached for maintenance.

MARINE-GRADE FIBERGLASS COVERS

Durable construction resists chemicals and impact. High-quality two-part epoxy protection.

PROCESSES 2CM TO 6CM STONE

Handles standard countertops and thick parts. Covers most decorative edge profiles.

VARIABLE FEED RATES: 4 INCHES TO 6 FEET PER MINUTE Adjust speed for material and finish requirements. Optimize for quality or maximize throughput.

OPTIONAL AUTOMATED RODDING AND DRIP EDGE

Expand capabilities with automation. Multi-purpose spindle available for specialized work.

ERGONOMIC DESIGN WITH PREMIUM COMPONENTS

Operator-friendly layout reduces fatigue. Reliable components built to last.

HIGH SPEED POLISHING

WE ARE LINE MACHINE EXPERTS

Fabricators choose Sasso machines because they're straightforward to operate, simple to maintain, and built to last. Value engineering focuses on reliable performance that reduces costs and maximizes productivity. Sasso brings value.